۹ Pointers to Thermal Fluid System Design

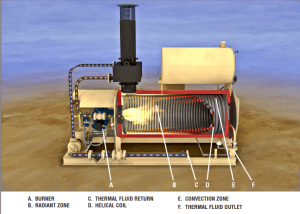

Thermal fluid heating systems provide an efficient source of heat for processes that require temperatures as high as 750°F (399°C). They are often less expensive to operate than steam systems and usually require less maintenance. In addition, thermal fluid heating systems do not lose heat to the atmosphere through traps and leaks as steam systems do.

Key to the low cost of ownership and operation of a thermal fluid heater is the simplicity of its design and the safety inherent in its low pressure operation. However, certain critical factors must be considered when designing a thermal fluid system. Addressing these issues will help to ensure the long service life and reliable operation of any thermal fluid system.

- Heater Sizing and Selection

When sizing a thermal fluid heater, consider the maximum anticipated BTU requirements, operating temperature and flow rate requirements. Also, examine system losses (typically ranging from 10 to 20 percent) as you determine the heat load.

Once the heat load is determined, a heater can be selected. Fuel-fired and electric hot oil heaters are available in both vertical and horizontal designs. Coil type thermal fluid heaters offer two-pass, three-pass or four-pass models, indicating the number of times combustion gases pass over the coil(s). Consult with the heater manufacturer for the best choice based on operating parameters, fuel, footprint and efficiency considerations.

- Pump Selection

The thermal fluid pump is a key part of any thermal fluid system. When selecting a pump, consider the operating temperature, cold start temperature and the properties of the thermal fluid the system uses. Pump motors should be selected based on cold-start conditions and run-out or end-of-curve horsepower requirements. Air-cooled pumps are available for operating temperatures as high as 650°F (343°C). Although they tend to be more costly than air-cooled pumps, water-cooled pumps are another option. For critical applications or cyclical heating/cooling applications, consider using a sealless pump

- Expansion Tank Size and Selection

Thermal fluid expands in volume when heated. As a result, a properly designed hot oil system must include an expansion tank that is sized to accommodate the expanded volume of the system. When selecting a tank, consider the system volume (including the initial fill of the expansion tank), the operating temperature and the fluid’s coefficient of thermal expansion. Because thermal fluids expand at different rates, the expansion tank capacity always should be verified against the fluid properties prior to filling the system.

Expansion tanks may be non-code vessels. However, if the tank must be pressurized to more than about 10 psig, an ASME Code tank should be considered — and may be required by local code or insurance requirements. Pressurization is a function of the tank’s location and design as well as the fluid’s vapor pressure.

- Insulation

Saturated insulation represents a potential safety hazard. Therefore, closed cell insulation that — in the event of an oil leak — will not absorb thermal fluid is the insulation of choice for hot oil systems.

- Piping System

As you consider the piping system, check to be certain that the components in the system meet the system’s temperature and pressure requirements. Carbon steel, cast steel, stainless steel and ductile iron are materials suitable for use in hot oil systems. However, brass, bronze, aluminum and cast iron are not acceptable.

It also is important that connections larger than 1″ be flanged or welded. Additionally, local code may prohibit threaded fittings. Finally, the piping should be pneumatically tested for leaks prior to filling the system. Hydrostatic testing of the system is not recommended.

- Flow Control

It is imperative to maintain proper flow through the thermal fluid heater under all conditions. A low flow condition can result in overheating and fluid degradation, which may ultimately lead to pump or heater failure.

Manufacturers typically employ safety interlocks to ensure proper flow at all times. These interlocks may be pressure switches or flow switches. When designing the piping system, install manual or control valves in such a manner to ensure flow to the heater is never compromised. If two-way control valves are used, a mechanical or pneumatic backpressure-relief mechanism should be installed.

- Temperature Control

Temperature control requirements dictate system design. Within the modulation range of the burner provided, most heaters can control temperature to ±۵°F (±۲٫۷°C). If the heater cycles off, the system could lose up to 50°F (28°C), depending on the system size, quality of insulation, etc. If tighter temperature control is required, a primary/secondary loop system may be employed. With the primary loop operating 25 to 50°F (13 to 28°C) above the required secondary loop temperatures, even if the heater cycles off, temperature control of ±۲°F (±۱٫۱°C) may be achieved.

The use of primary/secondary loop systems also allows multiple users to operate simultaneously at different supply temperatures. Modulating thermal fluid control valves also may be used to control the thermal fluid flow to individual users. However, the supply temperature to each user will be identical unless a primary/secondary loop system is used.

- Fluid Selection

Selection of the thermal fluid best suited to your application is important. Factors to consider include:

- Thermal stability.

- Adaptability to various systems.

- Physical properties such as the coefficient of heat transfer, vapor pressure, viscosity, freezing point and flash- and firepoints.

Heat transfer fluids of both mineral and synthetic origin have been specially developed to provide thermal stability over a wide range of temperatures.

In every case, it is imperative to strictly adhere to the safe maximum bulk temperature of the fluid. The safe maximum temperature varies according to the fluid, but a typical maximum for many types of mineral-oil-based fluids is 600°F (320°C). Take special care when consulting fluid manufacturers’ literature because the maximum fluid temperatures that are quoted are actually the limit to which any of the fluids may be subjected.

It is also important to remember that in any fired heater, there exists a “film temperature,” which is higher than the temperature of the “bulk” of the fluid. It is the bulk fluid temperature — not the film temperature — that the instruments indicate. Hot oil flow rates are a critical variable when sizing the pumps to ensure that the maximum acceptable film temperatures are not exceeded.

- Electrical Controls

Finally, always consider the location of the heater when determining the NEMA rating of the controls. General-purpose and watertight controls are the two most common. If the location is in a classified area, then controls suitable for Class 1, Division 1, or Class 1, Division 2, area classifications may be supplied. Hot oil systems also can be designed to include a PLC for first-out annunciation, sequencing controls and to interface with process or building management systems.

Designing a thermal fluid system requires attention to detail as each component of the system is selected. By carefully considering the nine items outlined in this article, you increase the likelihood of designing a system that best meets heating demands in an efficient, cost-effective manner while ensuring the system’s reliability and long-term longevity.

وب سایت آموزشی طراحی یوتیلیتی و فرایند مهندسی شیمی و مکانیک (طراحی یوتیلیتی و فرایند)

وب سایت آموزشی طراحی یوتیلیتی و فرایند مهندسی شیمی و مکانیک (طراحی یوتیلیتی و فرایند)